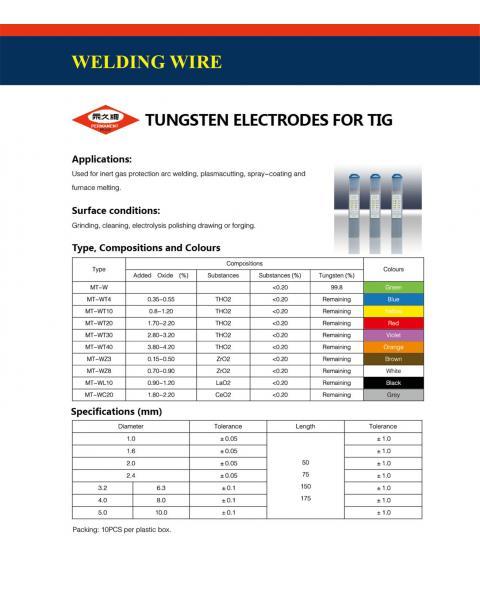

Tungsten Electrode For Tig

Applications: used for inert gas protection arc welding, plasmacutting, spray-coating and furnace melting.

Surface conditions: Grinding, cleaning, electrolysis polishing drawing or forging.

Type, Compositions and Colours

Type | Compositions | Colours | |||

Added Oxide (%) | Substances | Substances (%) | Tungsten (%) | ||

MT-W | <0.20 | 99.8 | Green | ||

MT-WT4 | 0.35-0.55 | <0.20 | Blue | ||

MT-WT10 | 0.8-1.20 | THO2 | Remaining | Yellow | |

MT-WT20 | 1.70-2.20 | THO2 | <0.20 | Remaining | Red |

MT-WT30 | 2.80-3.20 | THO2 | <0.20 | Remaining | Violet |

MT-WT40 | 3.80-4.20 | THO2 | <0.20 | Remaining | Orange |

MT-WZ3 | 0.15-0.50 | ZrO2 | <0.20 | Remaining | Brown |

MT-WZ8 | 0.70-0.90 | ZrO2 | <0.20 | Remaining | White |

MT-WL10 | 0.90-1.20 | LaO2 | <0.20 | Remaining | Black |

MT-WC20 | 1.80-2.20 | CeO2 | <0.20 | Remaining | Grey |

Specifications(mm)

Diameter | Tolerance | Length | Tolerance | |

1.0 | ±0.05 |

50 75 150 175 | ±1.0 | |

1.6 | ±0.05 | ±1.0 | ||

2.0 | ±0.05 | ±1.0 | ||

2.4 | ±0.05 | ±1.0 | ||

3.2 | 6.3 | ±0.1 | ±1.0 | |

4.0 | 8.0 | ±0.1 | ±1.0 | |

5.0 | 10.0 | ±0.1 | ±1.0 | |

Packing: Plastic box in bundles.